3GA Marine Ltd. is leveraging the advanced computational developments of 3D laser scanning and photographic scanning to augment our traditional marine engineering services at the implementation engineering level.

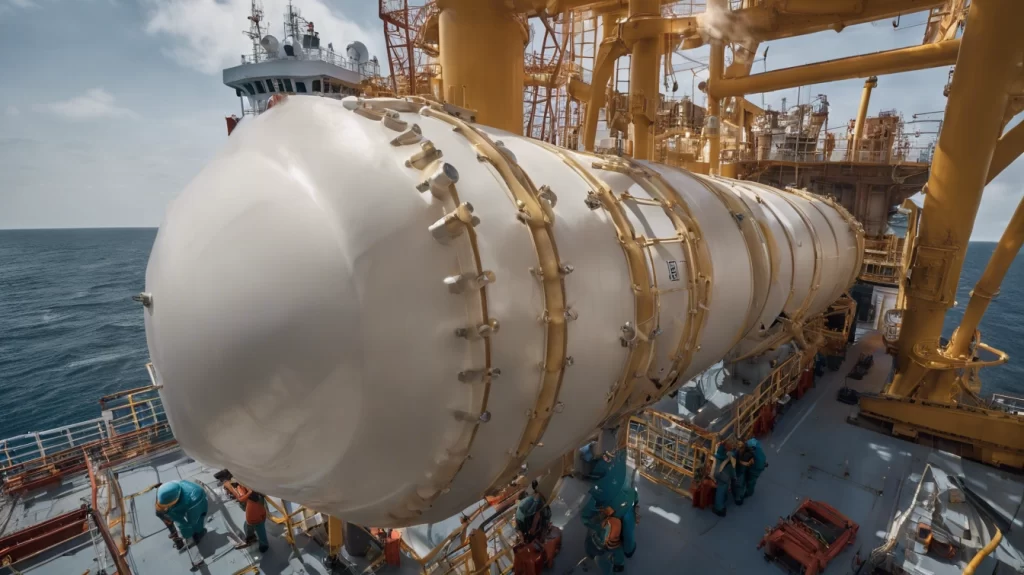

3D scanning provides increased accuracy and crucial data visually to vessel owners, operators, and shipyards. This allows construction teams to develop workflow plans virtually while reducing construction risks, costs and time that the vessel is out of service.

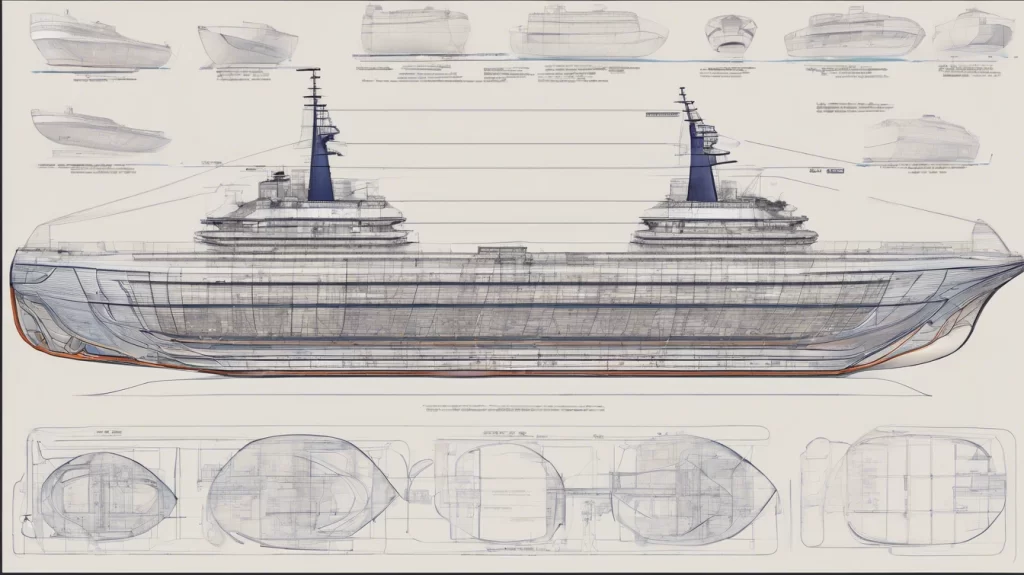

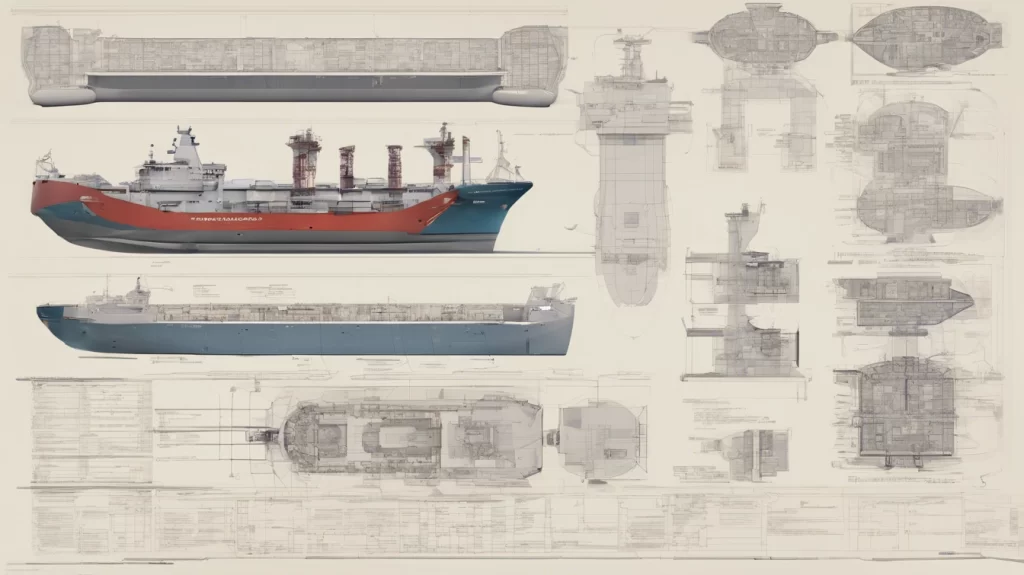

3GA can create as-fitted 3D representations of the actual space, build analysis, and interference models giving our designers/engineers the ability to accurately design modifications digitally. 3D technology provides 3GA Marine the opportunity to create implementation drawings of components that are highly accurate and give our clients the confidence that our designs are both efficient and cost effective.

Exterior hull scanning – with the use of 3D scanning, existing vessels can be converted into digital form, with confidence and accuracy. Existing vessels without documentation can have class level drawings developed for any range of class submittal, in a fraction of the time using 3d technology. Deliverables like vessel stability can become critical for aging vessels, the accuracy of a 3D scan will give owners and their crew the confidence that the vessel meets or exceeds the safety standards that current stability regulations require.